Everyone likes bath bomb’s because they are fluffy and soft. However, for the package designers they are nothing less than a nightmare. The reason behind this difficulty is that it is not very easy to put down a piece of cloud into a package. The packing designers do not want the product to lose its fluff and softness before it reaches the market to be sold. There are loads of brands that have to deal with this giant issue of maintaining the product quality and still be able to get the product ready for selling. If the pillows are kept open from the sides, they would get dirty.

The perfect solution for Custom Bath Bomb Boxes

While storing them and shipping them from one place to another, they could be inflated due to the burden of weight. Therefore, a lot of thought and deliberation has to go into finding a perfect design for the Custom Bath Bomb Boxes. There was a time when the bath bomb stuffing material was sold separately from the Bath bomb containers. However, in this day of modern technological advancements it is impossible for the customers to go through so much trouble for a simple bath bomb purchase.

When the nightmare of designing the perfect packaging for bath bomb were upon the heads of the package producers, the world was becoming more industrialized and digitized. The machine and industrial helpers started to take over every other industry. This was quite the good news for the bath bomb packing designers. These experts started to look for new ways for completing this task. There were loads of new solutions available thanks to the modern technology.

It was all about thinking outside of the box. The final solution that perfected the design of boxes was a miracle of packaging. Without proper knowledge of the scientific rules it would not been possible for the packing experts to find this solution. The bath bombs were fluffy due to the presence of air content in them. When these bath bombs were vacuum sealed, they become stiff. This material was able to be fitted into the shipping containers with ease and without losing its elasticity. Once the seal was broken the air would be filled automatically due to the atmospheric pressure. This little innovation almost revolutionized the market.

The Importance of Custom Boxes with Logo

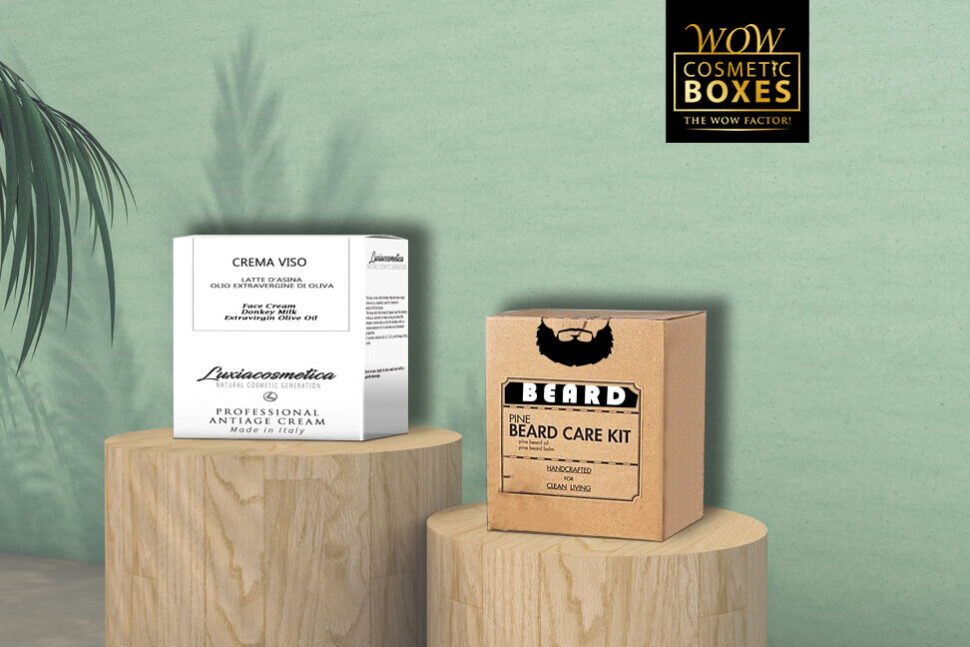

Logo plays an important part in making a brand seem more legitimate. Without a brand logo the customers would be unable to recognize any product. There are so many similar brands in the market place. Therefore, it is important for every individual manufacturer to mark their products with their own logo. In this manner, segregation would be made possible. The value of a product is associated with it brand and manufacturing identity. Without a logo it is not possible for the manufacturers to design a package at all. Almost no person would want to purchase a product that does not have a name on it. The products that are being sold for many years are able to gain recognition in the market place for their logo. It is also very helpful for the customers to find the right products with the help of the logo. Therefore, almost all the packages are centered on logo of the brand. To prepare a good enough Custom Boxes with Logo.

Here are some important factors that should be kept in mind:

- The logo should be placed in the central position. If the design of the background is overpowering the main logo, it could result in loss of sales.

- The logo should not be flamboyant and cheap. There are many brands that seem to go for unconventional font styles and colors to make sure that the logo is visible. Best to keep things simple and logical.

- The logo should clearly represent the brand value. A soap bar should not look like a fruit bar that is edible. Sometimes, the brand logos become misleading and vague. Therefore, it is important to make sure that these logos are pointed and focused.

- The logo should not look like artificial and very formal. The purpose of the logo is to bridge the gap of communications between the brands and the products. A logo should be able to put the customers at ease and not puzzle them about the meaning.

- The logo should be followed by a tag line. This service tag line compliments the main logo in a great way. The customers may not be able to find meaning in the name of the brand but the service message would make their products more relevant.

- The brands should be able to have a different logo for different types of products. Each logo is also a symbol of the type of the product that is to be sold. Therefore, it is not a great idea to sell every type of product with the same type of logo.

- The Logo should be able to inform the customers about the identity of the brand. The logo design and font style confer this brand identity into the minds of the buyers.

- The brands should not only keep the logo central focal point on the packaging but also try to get people to associate their brand names with the help of this logo.

Custom Soap Boxes – Significance and Uses

These were some of the biggest factors that impact the design of a product. Don’t forget to check out the latest Custom Soap Boxes on the official website that can take your brand on a whole new success journey. For the bathing products manufacturers, there are various ways they can enhance the outlook and beauty of their soap bars and other kinds of bathing items. The packs are made from cardboard which provides ease of shipping even to the longer distances and offer the opportunity to do marketing and advertising of their company in front of the customers and onlookers at the retail shop.